Bacterial inoculant for litter and pens

WHY SHOULD WE CONTROL THE MICROBIAL ECOSYSTEM OF THE LITTER?

THE LITTER AND PENS ARE THE BIGGEST RESERVOIR OF BACTERIA ON A GAMEBIRD FARM

by Ivan Girard, PH.D., PAS, R&D Manager, President of Probiotech International Inc.

Published on NAGA News September/October 2021 Issue.

The litter has many functions. Even if these functions are sometimes contradictory, they need to be consolidated. While its role of absorbing animal waste is permanent, the litter protects young animals from the floor, the cold temperature, and the humidity during their first weeks of life. It must be deep enough and loose enough to assume this role fully since the degree of insulation depends on the air present between the floor and the animal. This insulation property is slowly altered by the accumulation of animal waste, which increases the packing of the bedding and reduces the amount of air in it, while increasing the accumulation of nitrogen, feed residues and water. These physical and chemical changes modify the properties of the litter.

Before the introduction of the animals, the material starts out as an inert medium. After, it is transformed into a genuine biological reactor; a site where many fermentation reactions take place and whose im-pacts will affect the litter, the environment, and the animals.

On a poultry farm, where most of the buildings are sealed, continuously managing the quality of the litter is a key factor for the development of the animals. Besides the permanent contact of the birds’ legs and bodies with the litter, they are also subject to gas emissions linked to the biological reactor’s activity created by the soiled litter. Therefore, it’s important for producers to be aware of the major physical, chemical, and biological changes of the litter when animals are present. This way, they can control these changes to avoid health problems and to prevent the deterioration of housing conditions.

New litter has a very high dry matter content (often more than 80%), is very rich in carbon compounds containing a small amount of soluble sugars and has a low level of nitrogen with no soluble nitrogen. These characteristics change over time, because of the presence of animals.

The litter accumulates different elements from the animal wastes and becomes the site of numerous biological reactions. Four major elements accumulate in the bedding, and three of them are critical: nitrogenous constituents, water, and biomass from the intestinal microflora. The feed residues eliminated in the manure will only serve as biochemical complements for the different biological reactions that will take place. The structure and quantity of the different nitrogen compounds are crucial. Because of the high nutritional requirement for nitrogen, the manure will also be rich in this element. However, the nitrogen will be present in a degraded form, characterized by its solubility and high concentration in ammonia, which will transform in gaseous ammonia. In the case of chickens, which continuously move around the bedding, the water is mostly eliminated by evaporation. As for turkeys and ducks, which pack the surface, the water stays in the bedding and tends to end up in the deeper layers, where there will be anaerobic fermentation.

All these changes create a complex fermentation system where we can find, from top to bottom, in thick bedding, aerobic, facultative anaerobic and strict anaerobic reactions. These different layers are also characterized by the development of a specific bacterial flora, which will determine the types of fermentation that will take place.

During the rearing period, the manure is the main source of microorganism. These microorganisms bring a very abundant and diversified flora (1–10 billion bacteria per gram of bedding). However, these bacteria are mainly “strict anaerobes”, and they won’t be able to survive or grow in the aerobic conditions of the litter surface. Only “facultative anaerobes” will be able to multiply. These bacteria are mainly enterobacteria and coliforms which, even if not direct pathogens, can become a problem for weaker or young animals when present in concentrations over 100,000 bacteria per gram of bedding. These colonies also represent starting points of development for some pathogens such as E. coli, Salmonella, Staphylococcus, Entero-coccus, etc. These negative developments can be avoid-ed by orienting the microbial buildup of the litter by applying specific bacterial inoculants, such as BIOTANIX® WS, on the litter before the animals are brought in.

BIOTANIX WS was developed by Probiotech International Inc., following research projects conduct-ed with the Veterinary School in Saint-Hyacinthe, Quebec, Canada and with the US National Poultry Research Center Laboratory in Athens, Georgia.

The first phase of development demonstrated the ability of the beneficial strains of BIOTANIX WS to directly inhibit the growth of pathogenic avian strains: Clostridium perfringens, E. coli and Enterococcus cecorum.

The second phase led by Rothrock, and his colleagues (2019) assessed various doses and types of applications of BIOTANIX WS on the litter, during an eight-week incubation period. The samples collected each week allowed the research team to follow the bacteria populations over time.

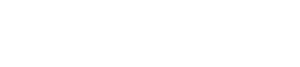

The results have enabled us to finalize the BIOTANIX WS formulation and to deter-mine the application type of the product on new litter for birds when they are introduced to a house. These scientists have demonstrated that one application of BIOTANIX WS at day 0 reduced significantly from 100 (2 log) to 1000 (3 log) times the concentration levels of enterobacteria, total coliforms and Clostridium in the litter at 42 days (Figure 1).

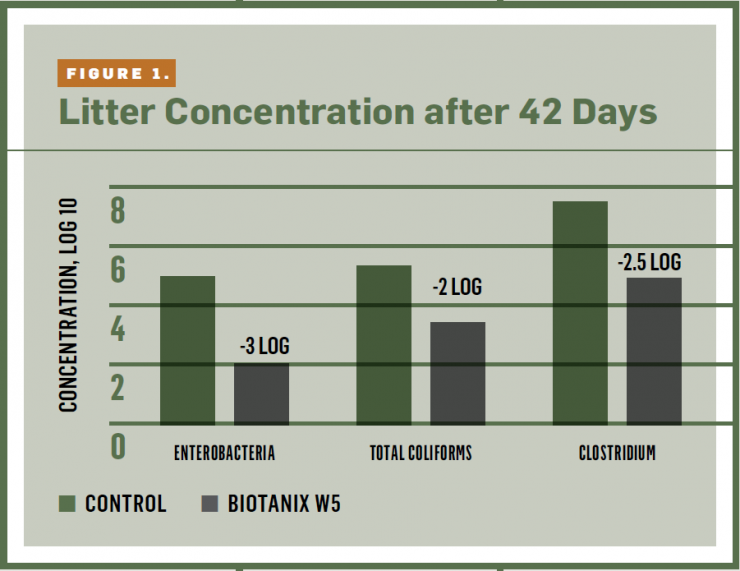

A series of field tests in Canada were conducted and supervised by avian veterinarians to show the impact of BIOTANIX WS on the litter of broiler flocks severely affected by Enterococcus cecorum. These trials have shown that a double application of BIOTANIX WS (on the ground, the walls and on the wood shaving litter) had a significant impact on the reduction of the Enterococcus counts in the bedding on day 15 and day 31.

For gamebird operations, the litter in the brooding house is crucial to manage as these birds are developing their own microbiota, are stressed and are susceptible to gastrointestinal challenges. However, moving birds to flight pens does not resolve the microflora issue. If the brooding house had high levels of enterobacteria and coliforms, or pathogenic strains began to colonize, the microbiota of the bird is impaired prior to movement. Combined with the stress of movement, there is increased risk for gastrointestinal challenges within the bird, and increased shedding of pathogenic strains from the bird into the environment. This leads to contaminated pens. BIOTANIX WS can be used on gamebird operations in the litter of the brooding houses and applied directly to the pens and floor.

In conclusion, the litter and pens are the biggest reservoir of bacteria on a poultry or gamebird farm. Its development in a flock can cause microbial problems in birds. It is therefore essential to control and regulate the microbial flora of the litter to minimize the risks for the birds. BIOTANIX WS will reduce pathogen growth in the litter, by competitive exclusion, and will stimulate non-pathogen bacteria growth. This creates a positive rebalancing of the litter’s microflora. This strategy is part of a whole farm approach for the regulation of the general microbiota of the birds through feed, drinking water and litter. This is even more important given the current context of reducing antibiotic use.

ABOUT THE AUTHOR

Ivan Girard was born and raised on a dairy farm in France. He studied micro-biology at the University of Dijon (Fance) and obtained his Ph.D. at the University of Kentucky (USA) in 1996. Since then, he has been involved in the development and production of natural solutions based on pre/probiotics, botanicals and acidifiers for the animal feed industry. Since 2000, he is President and R&D Manager of Probiotech International Inc., a Canadian company manufacturing feed additives, water additives and litter additives for conventional, ABF and organic programs for livestock animals.